Storage Shed foundation tips

For Biohort Storage Sheds and Equipment Locker

A level foundation is essential for the successful assembly of our products. The Storage Shed is anchored to this foundation to withstand stormy weather using the fastening material supplied.

Points to note about the foundation Use of existing foundations

Points to note for the foundation

A level foundation is essential for the successful assembly of our products. The Storage Shed is anchored to this foundation (or with the floor frame available as an accessory) to withstand stormy weather using the fastening material supplied.

Ground conditions

A solid surface should be used, if possible. The SmartBasePLUS requires established, well-compacted soil.

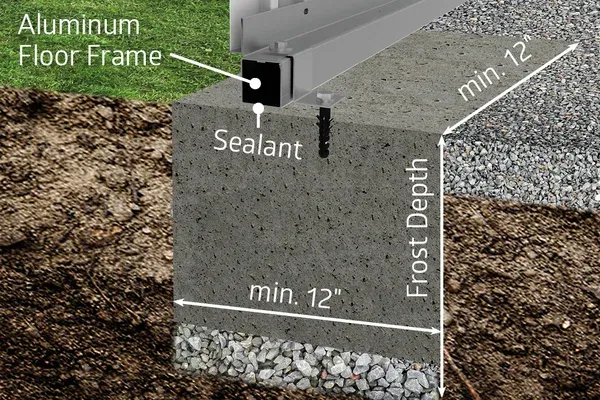

Foundation alignment and size

The foundation must be level so that the Storage Shed can be installed properly. If the product is on a slope, functionality may be limited (for example, the doors cannot be adjusted correctly) or the screw holes are not correctly aligned (holes do not line up). The foundation dimensions must be followed - please refer to the foundation plans.

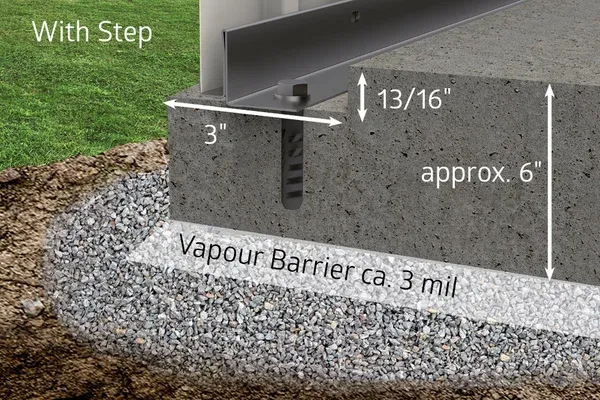

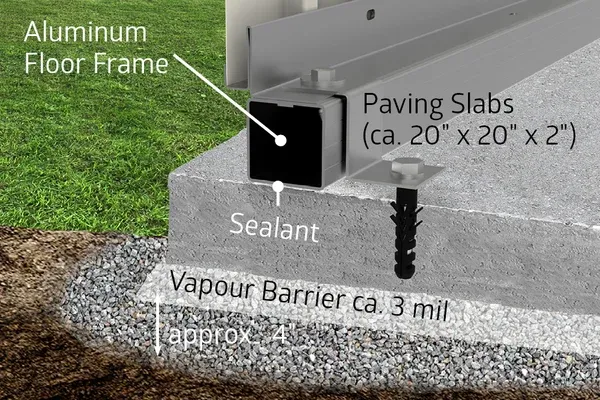

Vapour barrier

Plastic membrane with a minimum thickness of 150 μm = 0.15 mm

Ideally incorporate the membrane in the foundation. This is to prevent moisture from rising from the ground into the interior of the Storage Shed. Ensure that the membrane is not bigger than the surface area of the Storage Shed. This is because rainwater should be able to trickle into the ground sideways.

Sealing joint

The contact surface between the foundation and the aluminium floor frame should be sealed to prevent rainwater from entering the Storage Shed. The sealing is recommended in particular when using the aluminium floor frame.

A sealing compound is used as the sealant (suitable for outdoor use and metal). To ensure optimum sealing, the sealing joint should be applied beneath the floor frame. Please take into account that due to the nature of the ground (open-pore concrete slabs, joints, etc.), complete sealing is not possible.

Use of existing foundations

Existing surfaces can also be used as a base for Biohort products. If the existing surface is not ideal, proceed as follows:

The existing surface is not level

Recommended solution 1: Assemble the SmartBase

With the help of the SmartBase as a base, slight slopes can be compensated. It includes high adjustable feet that allow compensation of up to 1,5".

Recommended solution 2: Assemble the aluminium floor frame

Regardless of whether the surface is concrete or paved, you can put spacers underneath to level the floor frame. However, these spacers leave a gap under the frame, which allows water to penetrate or makes it more difficult to seal the Storage Shed. The spacers should, for example, be made from plastic or rust-proof metal such as stainless steel.

No vapour barrier was laid

Recommended solution: Subsequent installation of the vapour barrier using the aluminium floor frame

You can retrofit the vapour barrier by placing the membrane on the existing foundation inside the Shed. The ends of the membrane are pulled up along the inside of the floor frame and the membrane is folded inwards by at least 3,9". The folded section should also be glued. For a walk-on interior floor, our aluminium floor panel (lined with XPS panels) or any floor can be installed inside the Shed.

Use of stones that were too small/too light

Recommended solution: Weighting down of the ground mounting brackets of the floor frame

With a slab stone foundation, the internal floor mounting brackets (Z brackets) attached when using a floor frame can be weighted down with additional weight to increase storm safety.